The most common practices currently employed for finishing basement interiors as living space rarely account for the impacts that come with the added moisture load below grade, or the amount of heat that will be lost to the ground.

Existing basements are typically under-insulated or not insulated at all, and if they are, they almost always trap moisture within wall assemblies. This leads to preventable mold growth and rotting in basement walls - often caused by interstitial condensation.

The following basement insulation techniques listed here are designed to offer the most sensible and durable options for interior insulation, exterior insulation, or ideally, a combination of both.

These assemblies have been designed to prevent moisture infiltration over the service life of a building, along with allowing the original moisture contained in building materials to escape without causing damage.

Different types of insulation are included at different points in wall assemblies. For details and characteristics of different materials, see our page on choosing insulation.

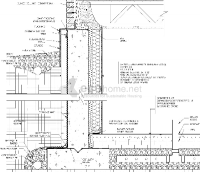

Insulation on the exterior and interior, from outside to inside:

- fiber cement board and parging above grade

- 3" of mineral wool or EPS foam (expanded polystyrene). 3" is better, 2" will suffice - not to be confused with styrofoam

- drainage mat

- damp proofing spray on exterior concrete wall

- 2" mineral wool board or EPS against interior concrete wall

- 2x4 stud wall with mineral wool batts in cavities

- drywall with latex paint as vapour retarder.

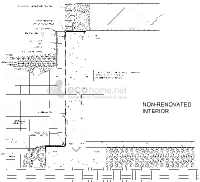

Interior insulation only:

- mineral wool board or EPS foam as thermal break against concrete wall

- 2x4 stud wall with mineral wool batts in cavities

- drywall with latex paint as vapour retarder.

Note: Not having proper exterior moisture protection for this wall assembly will mean moisture will migrate inwards. Mineral wool is not harmed by moisture, but there may be additional heating and coolling loads inccured by having higher relative humidity levels. Basement dehumidifiers can help keep keep humidity levels manageable. Please see our page on retrofitting existing basements.

Exterior insulation only:

- fiber cement board and parging above grade

- 4 inches EPS foam

- drainage matt

- bituminous damp proofing.

Best practices for new basement construction:

Ideal performance and durability is achieved by insulating both the interior and exterior of foundation walls. This technique can increase the thermal performance of basements, reducing heat loss and operating costs. It also helps reduce the chance of interior moisture issues by raising the temperature of the first interior condensing surface, the concrete.

Below is a thermal image of the basement described above with insulation on both sides. The effective R value of this wall amounts to R40. Three inches of EPS under the slab amounts to R12.6, There is a solid financial argument that can be made for increasing that, particularly with the inclusion of radiant in-floor heat.

|

|

Thermal image of basement insulation and heat loss © Ecohome

|

Exterior basement insulation is less common, probably due to the fact that it can be more expensive. And there are certainly less cases where insulation is installed on both sides. By insulating the exterior of basement walls, we consume less interior space and prevent exposing walls to the seasonal freeze/thaw cycle known as 'thermal shock' that can cause the cracking of foundations.

Insulating basement interiors rather than exteriors can be the cheaper option were you to choose just one, particularly if they are intended to be finished living space. It can also more easily address thermal bridging issues at the tops of walls, as well as the junction between footings and foundation walls.

As there is little consensus on basement design and materials used or the optimum level thermal performance, we fully expect there to be those that find this to be extreme and unnecessary in both durability and performance. We believe this stems from the fact that basements are currently dank and moldy, chronically under-insulated, and that we are simply accustomed to paying the high cost of heating.

Ecohome promotes as much as possible, a philosophy of heat retention rather than heat generation. Additional costs for insulation are often negated by monthly savings, and a well designed and insulated basement will have a much longer service life without repair.

One of the most commonly overlooked benefits of extreme insulation in homes is heat security, as extreme weather events in cold months routinely drive residents from their homes for lack of power and heat. Homes that are better situated to retain heat can offer greater comfort for a longer period of time in such situations.

Issues and solutions for all basement wall assemblies:

|

|

EPS spacer on bottom of framed basement walls © floodsill.com

|

Spacers below bottom plates: Shimming up bottom plates with backer rods or chunks of foam can be an added measure of durability in the event of any interior flooding, by allowing water to pass under walls.

Read all about how to stop basements flooding - flood prevention, pumps & alarms here

And how to use environmentally friendly materials for waterproofing basements here

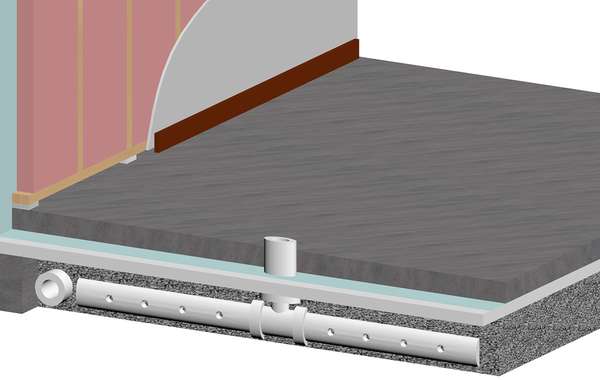

Slab floors: A large portion of heat is lost to poorly insulated basements, including below slab floors. The optimum levels of insulation below slabs varies by region and climate, but also by individual building site and soil conditions.

To save both money and energy, we recommend a minimum of R20 under slabs in most of Canada, at least along the Canadian / US border where most of Canadians live. Increased levels are recommended for more northern regions. Please see our pages on sub-slab insulation for more details.

|

|

Roxul mineral wool exterior foundation insulation © Roxul

|

Exterior EPS or mineral wool: Neither are harmed by moisture. With care they can be largely held in place against exterior walls with backfilling below grade, and fixed above grade with fiber cement board attached through to foundation walls.

Drainage: Regardless of the location or amount of insulation, foundation walls should be protected from ground water, which should be directed to properly sloped and perforated drainage tiles. Any backfill against walls should drain easily, and weeping tile drains should be covered with a geotextile membrane to prevent clogging. The inclusion of a clean-out junction in weeping tiles can allow for easy long term maintenance.

|

|

Foundation perimeter surface drain © Ecohome

|

A surface drain can be a valuable added measure of protection, as seen above on the interior and exterior insulation diagram.

This is highly recommended for metal roofs in particular as they notoriously shed eaves troughs as they shed snow. In the absence of eaves troughs (by choice or otherwise), roof water ends up at the perimeter of foundation walls.

|

|

Avoid wood to concrete connections in foundations © Ecohome

|

Avoid wood-to-concrete connections: Concrete foundations take five years to fully dry, and that is only if they are completely separated by exterior waterproof barriers from ground moisture and water. Without breaking the connection from dirt to porous concrete, foundation walls will never dry, and continue to wick moisture.

It is common practice to embed wood directly into concrete to frame window and door openings. Such practices put framing members at risk of rotting. Even with basements completely sealed at the exterior, wood will soak up all the available moisture in concrete.

|

|

Capillary break between footing and foundation © Delta

|

Capillary break: Footings are not protected from moisture at the bottom, the inclusion of a capillary break between footings and foundations prevents moisture from wicking into walls. There are dedicated membranes for this application, but 6 mil polyethylene will do the job as well, probably more affordably.

Insulated rim joists: This is a very tricky location to successfully insulate and air seal. Spray polyurethane foam (SPUF) is one of the preferred solutions to this trouble spot. When insulating basement interiors, SPUF can be installed to meet interior wall insulation, breaking the thermal bridge of floor sill plates.

Another effective technique can be insetting floor joists from the exterior of the concrete to allow continuous insulation of rim joists on the exterior.

Stud wall and batt insulation: Again, we recommend mineral wool for its higher R value, recycled content, and ability to withstand moisture. However, the risk of moisture damage is much lower at the stud wall compared to against the concrete, so mineral wool could be safely substituted with fiberglass batts if desired, particularly in areas of low flood risk.

|

|

Liquid applied vapour barrier primer © Benjamin Moore

|

Interior gypsum board: Latex paint (or vapour retarder primer) is recomended as an interior vapour control layer below grade. It is most important to not include a polyethylene vapour barrier or other vapour impermeable materials that prevent walls from drying.

6 mil poly vapour barriers are an above grade solution intended to allow walls to dry to the exterior, that is impossible below grade. The only drying that will take place below grade will be inwards.

Building scientists agree that polyethylene vapour barriers on the inside of basement walls dooms them to failure. The source of moisture we need to protect against is exterior ground and concrete, not interior relative humidity.

Now you know about the best way to buid and insulate a basement to avoid mold and heat loss. Find more pages about sustainable construction below and in the Ecohome Green Building Guide pages.

Discover all the benefits of a free Ecohome Network Membership here - promote your business and get access to discount pricing on select building materials! |

My contractor put Tyvek on the inside of the block wall, facing into the basement, then applied 2x4 studs directly over the Tyvek, batt insulation, vapour barrier, and finally drywall. I argued that Tyvek House Wrap was for the outside of the house, not the inside, also that an air gap should be between the block wall and studs, and finally at the very least the house wrap should be facing out and only on the area above grade. Our basement now feels damp, I can't help but feel that this is why? Advice?

Hello Caz, I am a contractor in PA.

There are varying thoughts on basement finishing and moisture retention. We used to put a plastic vapor barrier against the block, which was to protect the framing and act as a vapor/moisture barrier but it creates trapped moisture if you also use a faced insulation.

A couple questions:

1. Did he frame a wall with studs on end and use a top and pressure treated bottom plate or did he fur the studs to the wall flat?

2. Did he use kraft faced insulation?

What we do now is use a closed cell R-10 insulation board up against the foundation, caulk & tape the seams, and then frame a wall against the foam. You will also need to spray foam or caulk for draft stopping.

Then in areas that are more than 50% above grade, your interior walls need to meet current codes for insulation, so you will want to install non-faced R-13 insulation in those wall framing cavities. We are in Zone 5.

Any living space below grade is going to have a higher relative humidity and you should use a dehumidifier and try to keep the RH to below 30%.

All concrete is porous as well. We generally use Sika concrete repair on cracks and sometimes have use drylok or similar if we are aware of any water seepage or activity in a foundation wall.

Although tyvek is water and air "proof", it does allow a vapor transmission. Either way it's installed, moisture may sit against the block or against the insulation. Air flow is important as well and having a little space between the insulation and the wall will improve the insulation's effectiveness and give any standing moisture the ability to dry out.

Hopefully that helps. Also: I had an investment property that had a lot of moisture in it. I bought a good dehumidifier and connected the drain into a slop sink and bought a 220cfm basement window fan for $200 with a humidistat control and reduced the RH from 55% to 25% in less than a week. The CFM fan will pull air through your house, into the basement, and out to the exterior.

Hi, after reading many articles regarding insulation for the basement, shouldn't we not install 6 mil poly against the concrete slab and wall? However, the cross-sectional drawing above shows a vapour barrier against the concrete. Is that correct? Also, what is the best way to insulate an existing basement slab? Like how it shows on the detail above? Thanks!!!

Hi Bill

Adding vapour protection to the concrete like a 6 mil poly and then building your walls on the inside of that is a much safer way to do it. The concrete is the main source of moisture, so it's best to prevent it from entering your wall assembly. Basements in the mainstream industry are a bit better now than in years past, you now most often see the inclusion of a rigid foam panel against the concrete before the stud wall, and that is your vapour protection. XPS insulation is more expensive (and more polluting), but as little as one inch acts as a vapour barrier, and with EPS insulation it begins to act as a vapour barrier at about 2 inches.

I would always want a vapour barrier before the stud wall and none on the interior, that way I’ve stopped moisture from entering from outside, and moisture contained within the framing materials is able to escape into the air of the basement. That minute amount of moisture is far better out of your wall where it can be managed by ventilation systems or a dehumidifier, rather than being trapped behind a vapour barrier that is intended to keep moisture out but actually keeps moisture in.

Bill

I completely agree with your statement , i have an HRV and have never had a interior moisture issue. I believe the same block the dampness from penetrating fron the outside of the concrete wall and you will have a very comfortable basement.

I am finishing a humid basement and have already put up a stud wall AND firestopping, so it is not really that easy for me to simply hang whole boards of foam. In some sections, I am well more than 2" away from the block wall, and in others, I am about 1" away, so I cannot hit 2" of foam board everywhere. I am willing to cut foam boards into smaller pieces and fit them into the gaps, filling any gaps with spray foam, but I have a couple of questions about what I should do regarding my odd-sized gaps (no, I am not re-doing the stud wall).

1) Is having extra space between the 2" foam and stud cavities a problem? You are recommending building tight against, but I don't quite see why except for firestopping. (I already do have vertical firestopping plugging my gaps. I really didn't understand normal practices before building stud wall.)

2) Is having only 1" foam on the wall going to be a big problem? Do I definitely need the higher performance of XPS over there? I am pretty on board with rock wool in that section.

3) I am not fully understanding the recommendation for rock wool vs fiber glass. With foam board barriers, moisture does not really seem like a concern for fiberglass. Is there some other reason you like rock wool over fiber glass?

Thanks, hopefully you are still answering questions.

Hello! Arrived here as a self builder in zone 3a (North Alabama) doing a retrofit (full gut remodel) plus addition. I am starting out with a nasty crawl space which we will be converting into "mini basement" foundation. Could anyone comment on which basement insulation assembly is best for the hot-humid climate zone on Alabama red clay soil??